Gradient Optimization of Liquid Chromatography

1. Try to develop methods on instruments that can test the project for a long time.

2. It is necessary to understand the property of the system so as to avoid problems that it cannot be reproduced after changing the instrument system.

3. Two basic facts of the system should be known: gradient lag volume and proportional accuracy. These two data can be obtained in the same experiment: refer to the Experiment of Gradient Error in JJG 705 2014 Liquid Chromatograph Verification Regulation: add an ultraviolet detector after B solution (0.1% acetone), then set a multi-layer gradient. B solution changes from 0% to 100% at an amplitude of 5% while flow rate is the same as usual at 1mL/min. Each gradient is maintained for about 5min. Then connect two running gradient and record chromatogram. The difference between the set time of each gradient and the actual gradient time is the gradient lag time. The height of the layer can be used to measure the proportion of flow phase. These layers may be a little fuzzy, which caused by the mixing volume in the system.

4. After testing the system, you can design the method according to its properties. The biggest problem of gradient method conversion is gradient lag volume. If you know the lag volume of instrument is bigger than originally developed methods of equipment, please consciously add a gradient to offset the difference in the method. If the lag volume of target system is small, add a gradient delay time when transferring method. If the proportional difference occurs in the process of the gradient operation, you also can adjust the gradient chromatogram to offset the difference, but this rarely happens.

5. The initial mobile phase was not sufficiently equilibrated. The column had been equilibrated with the initial mobile phase, but in the analysis, the gradient changed rapidly. Once the column is not sufficiently equilibrated with the initial mobile phase, the first injection will be different from the next. But if you move to a system with a different lag volume, it might be a different case.

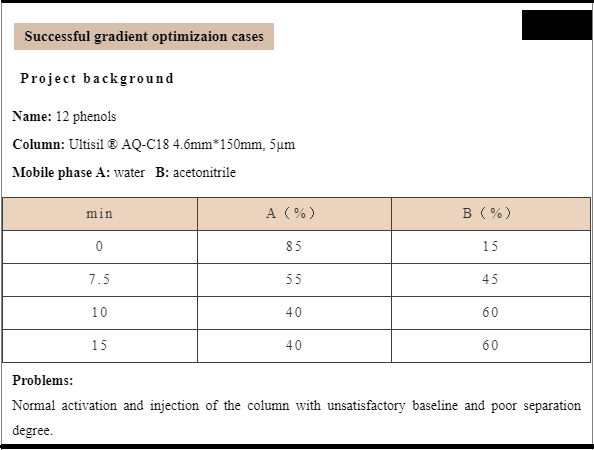

1. The preservation fluid of the column changes during transportation or storage, resulting in minor changes in the packing material. The carbon chain curled up and did not stretch out, affecting the retention of the target substance.

2. There is gradient lag in the instrument system. In the process of gradient change, the mixing of two phases is not accurate, resulting in material separation problems.

3. The target substance is affected by solvent effect;

4. The gradient changes too fast and the elution capacity of mobile phase is too strong, so the peak failed to achieve separation effect.

1. Test the accuracy of gradient lag volume and proportion.

2. Equilibrate the column overnight with the initial mobile phase at the flow rate of 0.2.

3. The sample shall be dissolved with the initial mobile phase (cautiously, the stability of the sample solution shall be verified after changing the sample solvent).

4. Adjust the gradient to slow down the elution rate and reduce the elution capacity.

Comments

Post a Comment